A 3D printer for faster and more effective quality control

Precision turned component prototypes

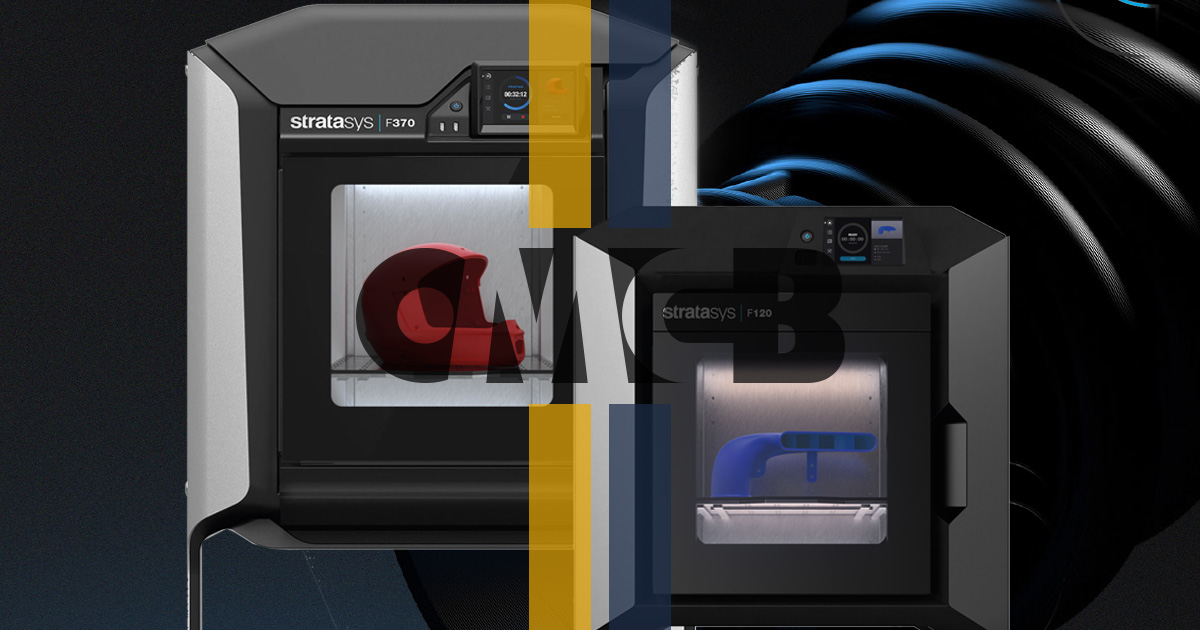

Starting from technical drawings, the 3D Printer Stratasys F123 creates plastic or resin prototypes of the components that will then be produced in steel, metal or copper using machining centres or automatic lathes. This allows us to obtain exceptionally precise and complex prototypes, in record time and perform final tests, measurements, tightness tests, before commencing series production with greater levels of awareness and no time wasted.

Brackets for the quality department

With custom drawings prepared in-house by our technical department, the 3D printer is used to realise plastic brackets and supports that hold the components still during quality control operations performed using equipment like Zeiss Contura or the Jenoptik system. Plastic brackets facilitate quality control operations, achieving more accurate measurements and make the whole process leaner, reducing the use of the machining centres that can now be dedicated exclusively to the realisation of the mechanical components.