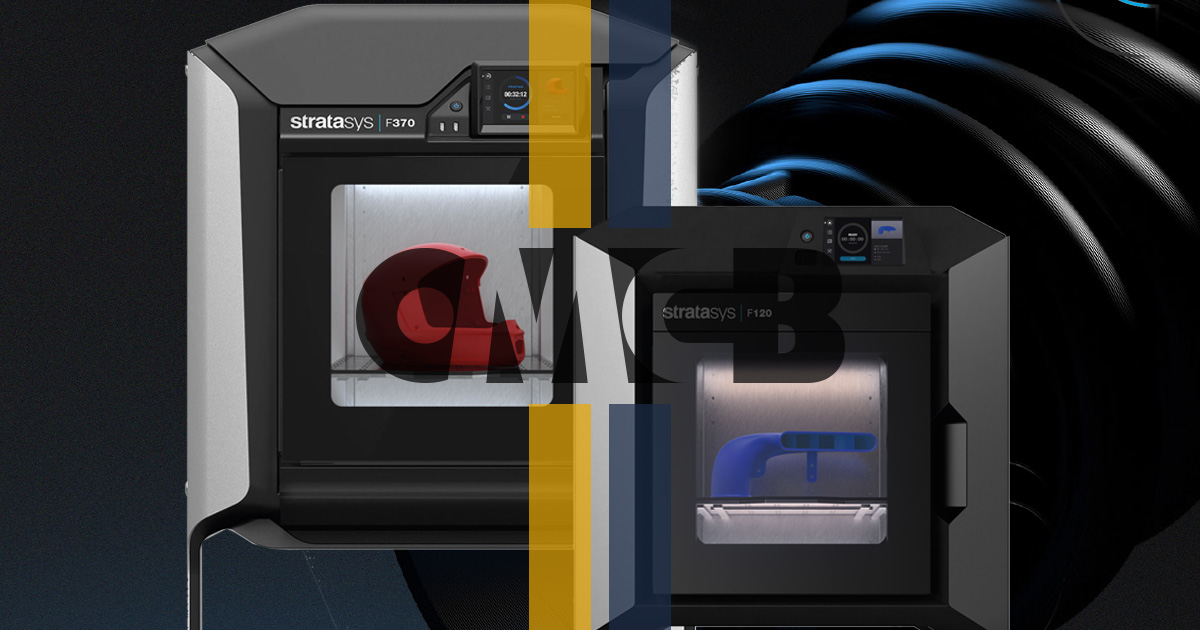

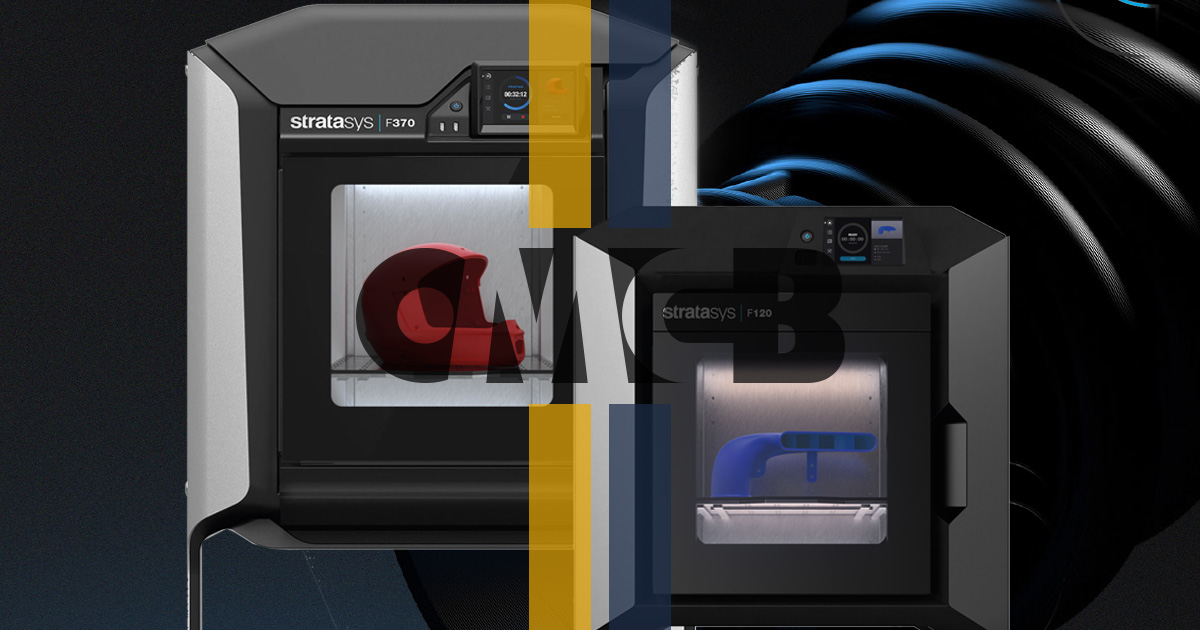

A 3D printer for faster and more effective quality control

We continue our investments in quality control machinery with the purchase of a 3D Stratasy F123 printer, for swift realisation of more precise brackets and prototypes.

Turning machines

Machining centers

Cnc adjustments

Testing centres

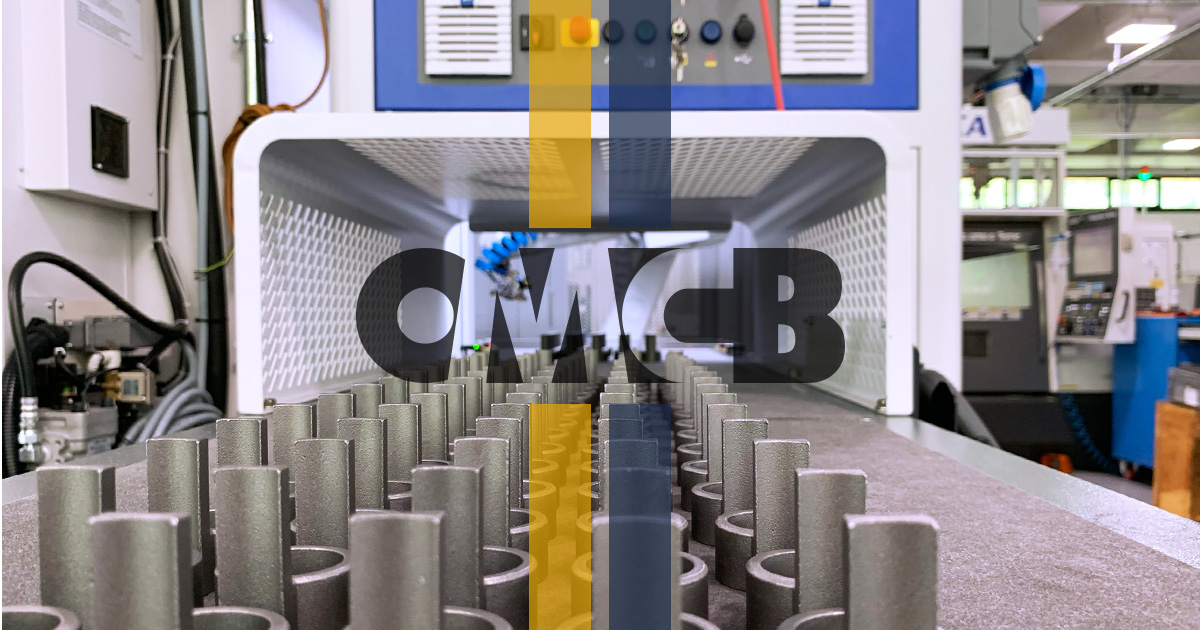

Since 1965, OMCB has specialized in contract machining for the production of customized mechanical parts, serving a wide range of industrial sectors:

With 60 years of experience, we combine quality, precision, and innovation in every component we produce.

Our production process adheres to rigorous standards, ensuring maximum precision and long-lasting durability in every mechanical component.

We analyze the surface and composition of each material to ensure proper storage of every component.

Hot molding and lost-wax micro-casting guarantee precise, high-performance components. Cutting with automatic hacksaws ensures consistent quality and efficiency.

We perform mechanical machining on fixed-head lathes (up to 600 mm), mobile-head lathes (3-40 mm), and 5-axis machining centers (up to 900 mm).

Components undergo heat and surface treatments to enhance resistance and durability.

Dimensional inspections, mechanical tests, and destructive testing are performed to ensure compliance with technical drawings.

Each component is carefully packaged to protect it from moisture and condensation during transportation.

Pieces produced

Operators

Operational offices

M2 of production unit

"We believe in quality, attention to detail and innovation. These values, combined with our passion and strong desire to grow, have made OMCB an Italian reality appreciated throughout the world."

CEO

We maintain the highest international standards of quality, safety, and sustainability.

Our certifications demonstrate OMCB's continuous commitment to providing innovative and environmentally responsible solutions.

We continue our investments in quality control machinery with the purchase of a 3D Stratasy F123 printer, for swift realisation of more precise brackets and prototypes.

Our Bovegno facility unit machinery fleet now includes a new Brother Speedio rotary table machining centre that performs integrated turning and milling processing.

The application of the Mechatronics principles at our facility in Bovegno automates production and allows us to dedicate more time and attention to control activities and quality

Do you need custom-designed mechanical components?

At OMCB, we produce tailored parts in steel, brass, copper, titanium, and aluminum alloys, ensuring quality, precision, and durability in every component.

Fill out the form below, and we will get in touch with you promptly.