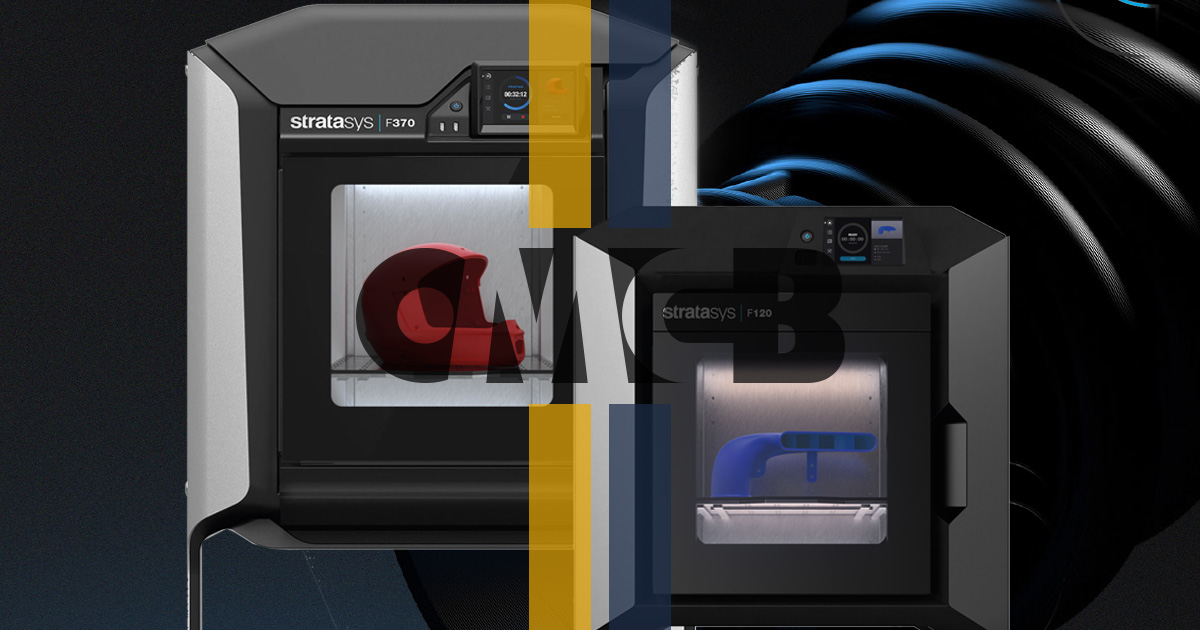

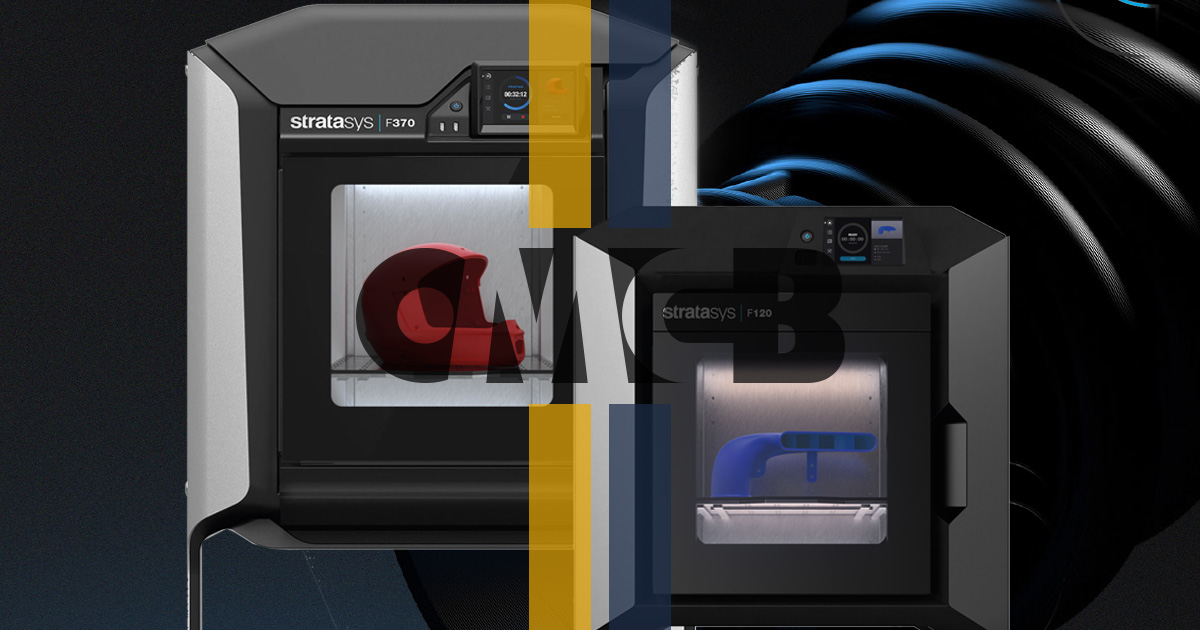

A 3D printer for faster and more effective quality control

We continue our investments in quality control machinery with the purchase of a 3D Stratasy F123 printer, for swift realisation of more precise brackets and prototypes.

On this page, you can find the latest news and updates from our company in the field of contract mechanical parts production. Stay informed about innovations and trends in the world of precision machining.

We continue our investments in quality control machinery with the purchase of a 3D Stratasy F123 printer, for swift realisation of more precise brackets and prototypes.

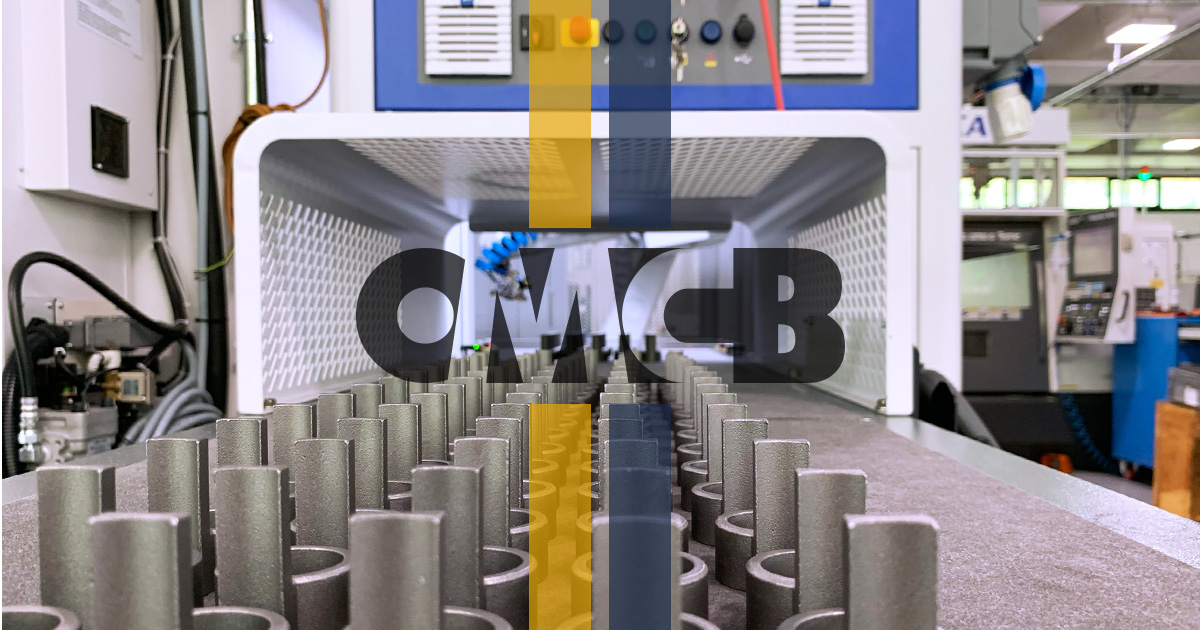

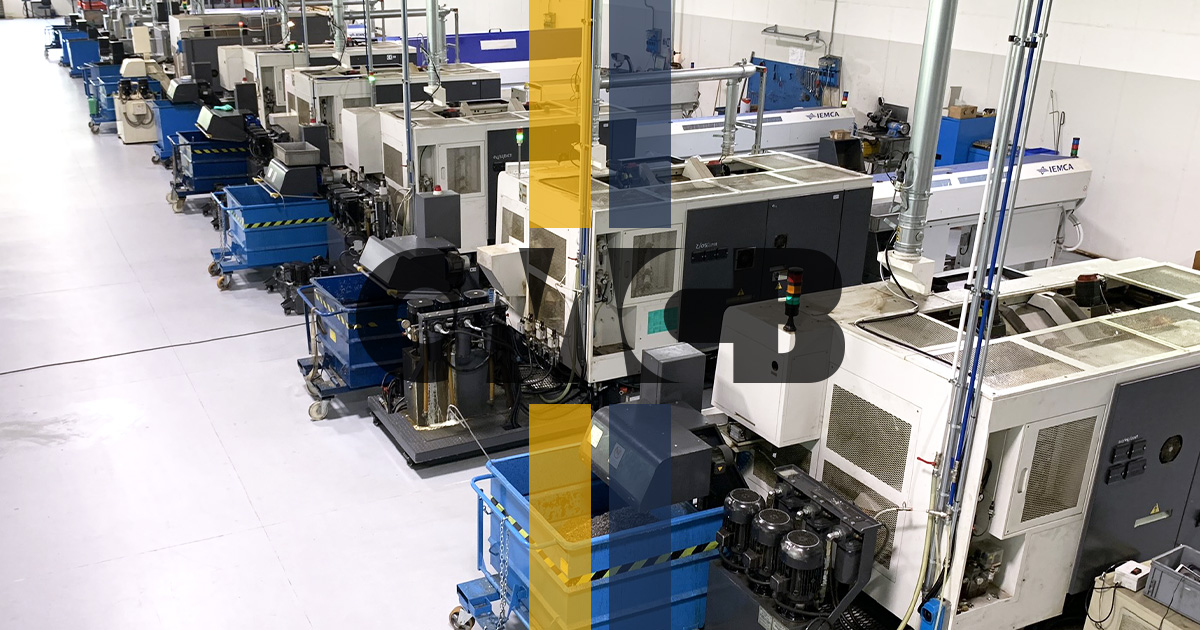

Our Bovegno facility unit machinery fleet now includes a new Brother Speedio rotary table machining centre that performs integrated turning and milling processing.

The application of the Mechatronics principles at our facility in Bovegno automates production and allows us to dedicate more time and attention to control activities and quality

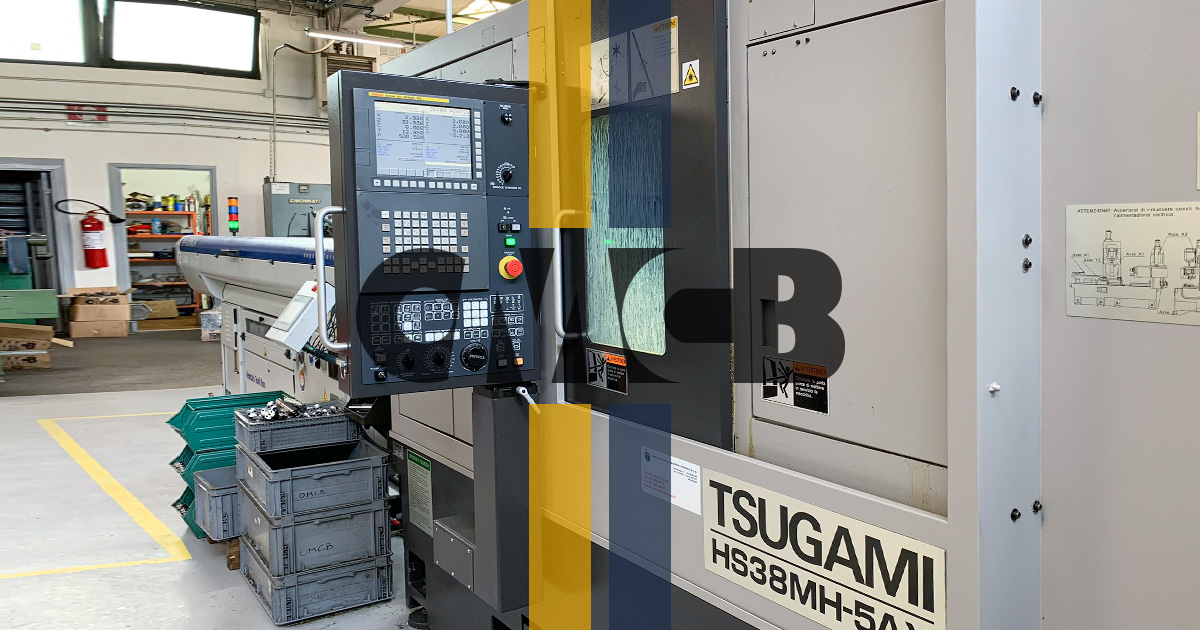

Our investments in Industry 4.0 continue with the purchase of the new automatic Tsugami CNC HS38mh 5AX lathe. Discover the details of the new potential capabilities we can offer The new multitasking Tsugami HS38mh-5ax sliding head lathe is finally up and running at our facility unit in Collio, one of the first new generation lathes […]

Industry 4.0 and mechatronics for quality: this is what we brought home from our experience at the JIMTOF 2018 in Tokyo, the machine tool fair par excellence. Sector fairs are a training moment for enterprises which, like us, are always on the lookout for updates in the Industry 4.0 and mechatronics. Mechanical engineering trade fairs […]

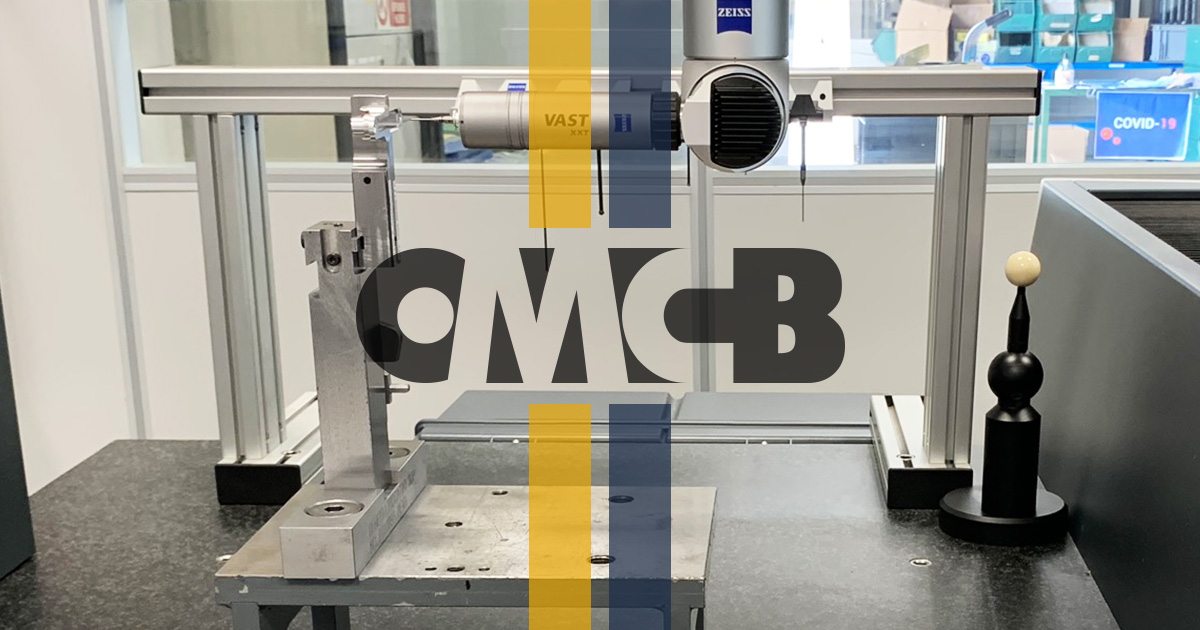

Our quality department now boasts a ZEISS Contura tool, a must-have machine for quality control procedures required by ISO 9001:2015. Discover its potential. The ZEISS Contura system was recently introduced to our quality department, an innovative bridge-type measuring system providing even more precise component control. A must-have system to obtain ISO 9001:2015 certification, something we […]

We recently purchased a JENOPTIK Hommel Etamin, an optical system specifically designed for turned components, to guarantee increasingly precise quality control. Here are the advantages of this system. The quality assurance department at our plant facility in Bovegno is always looking for innovative tools and machines for the control of turned components, and this year […]

Two factories with one single digital production control system: OMBC lays the foundations for Industry 4.0 In the special edition of the Giornale di Brescia dedicated to Industry 4.0, our company was named as one of the companies that has invested most in the technology and digitisation of its factory plants. For several years, in […]

Our historical headquarters in Collio is now joined by a new production unit in Bovegno where we perform machining to the superior quality levels that distinguish us.

Since 1965, OMCB has specialized in contract machining for the production of customized mechanical parts, serving a wide range of industrial sectors:

With 60 years of experience, we combine quality, precision, and innovation in every component we produce.

Our production process adheres to rigorous standards, ensuring maximum precision and long-lasting durability in every mechanical component.

We analyze the surface and composition of each material to ensure proper storage of every component.

Hot molding and lost-wax micro-casting guarantee precise, high-performance components. Cutting with automatic hacksaws ensures consistent quality and efficiency.

We perform mechanical machining on fixed-head lathes (up to 600 mm), mobile-head lathes (3-40 mm), and 5-axis machining centers (up to 900 mm).

Components undergo heat and surface treatments to enhance resistance and durability.

Dimensional inspections, mechanical tests, and destructive testing are performed to ensure compliance with technical drawings.

Each component is carefully packaged to protect it from moisture and condensation during transportation.

Do you need custom-designed mechanical components?

At OMCB, we produce tailored parts in steel, brass, copper, titanium, and aluminum alloys, ensuring quality, precision, and durability in every component.

Fill out the form below, and we will get in touch with you promptly.